Integrated Dc-dc Converter Design For Electric Vehicle Powertrain

Request PDF On Mar 1 2016 Saeed Anwar and others published Integrated DC-DC converter design for Electric Vehicle powertrains Find read and cite all the research you need on ResearchGate. In electric engineering a DC to DC converter is a category of power converters.

Reduce Ev Cost And Improve Drive Range By Integrating Powertrain Systems Automotive Technical Articles Ti E2e Support Forums

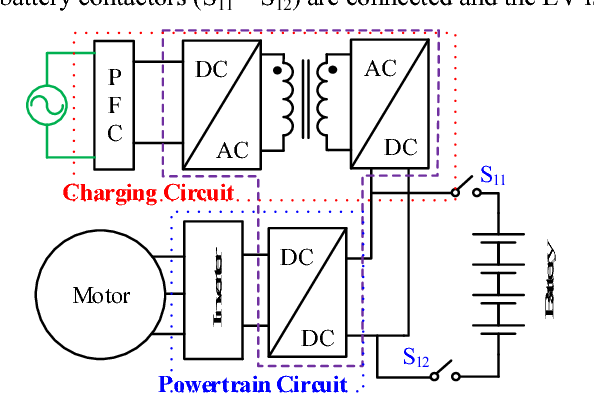

During charging the proposed converter functions as a DAB converter providing galvanic isolation.

Integrated dc-dc converter design for electric vehicle powertrain. EVs dont have alternators like most vehicles with. Its possible to apply integration at the mechanical. When we advance EV powertrain architectures our customers can cut system-design cost in half while maximizing power density increasing efficiency improving reliability and making EVs more affordable for more people.

The charging system consists of an ACDC rectifier to generate a DC voltage from the AC line followed by a DCDC converter to generate the DC voltage required by the battery pack. Eaton has vast expertise and a strong legacy of building highly reliable DCDC converters and can design custom solutions while leveraging standard. Thats the idea behind integrating electric vehicle EV and hybrid electric vehicle HEV designs.

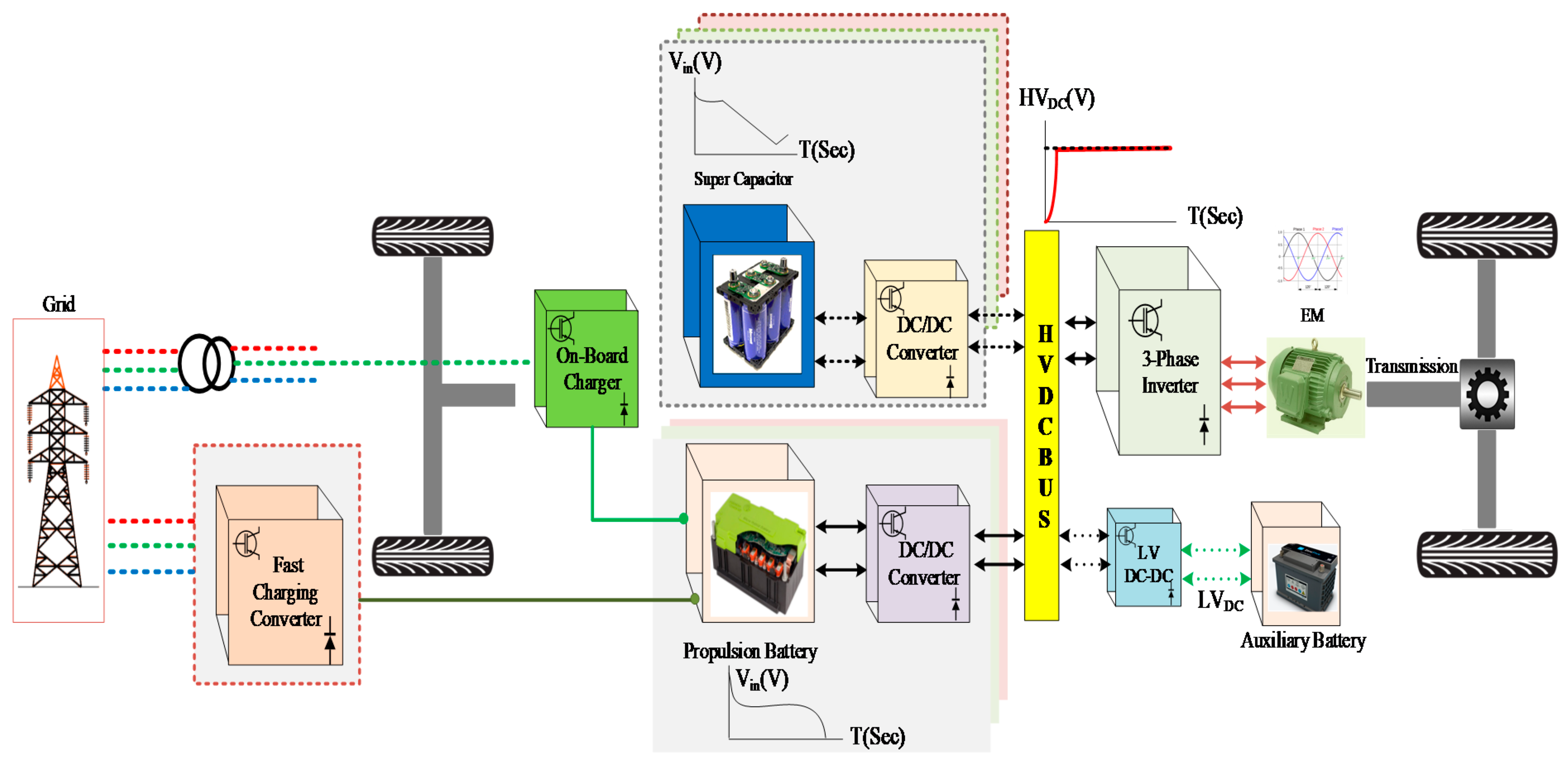

3Formerly Ficosa now owned by Panasonic. High performance and fast digital control loops enabling highly efficient powe. Powertrain integration combines end equipment such as the onboard charger OBC high-voltage DCDC HV DCDC inverter and power distribution unit PDU.

The converter integrates functionality for both EV powertrain and charging operation into a single unit. In electric vehicles which use a DC motor actually running the motor can use up to three times the voltage provided by the battery. For powertrain operation the converter functions as an interleaved.

In this work a DC-DC converter is designed for an electric vehicle. In this paper an integrated reconfigurable DC-DC converter for plugin and hybrid Electric Vehicles EV is proposed. Introduction to EV Design Component Overview DCDC converter Charger Inverter DCDC Converter Battery Pack - 12V Battery Electric Machine EVs to date utilize the same 12 volt power system as traditional vehicles for low to moderate power electrical components.

LTTS have developed and built a one-of-a-kind Electric Vehicle EV testing lab at our Bangalore delivery center to perform electric vehicle component testing. The converter integrates functionality for both EV powertrain and charging operation into a single unit. Representational image MEB powertrain platform for electric vehicles by Volkswagon.

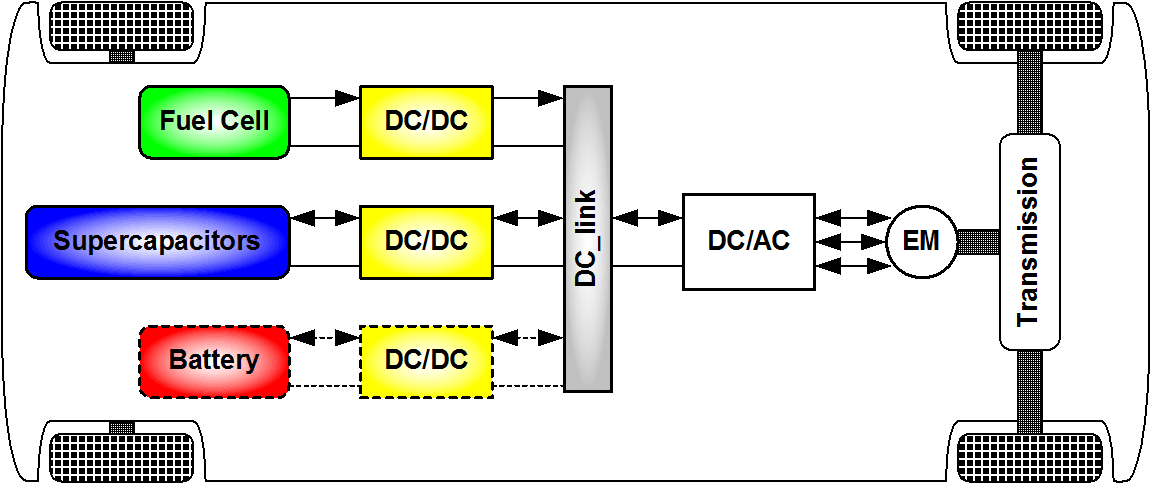

Electric vehicle sales are beginning to increase in popularity and the need for DC-DC converters. In a hybrid or electric vehicle powertrain a boost dc-dc converter enables reduction of the size of the electric machine and optimization of the battery system. In this paper an integrated reconfigurable DC-DC converter for plugin and hybrid Electric Vehicles EV is proposed.

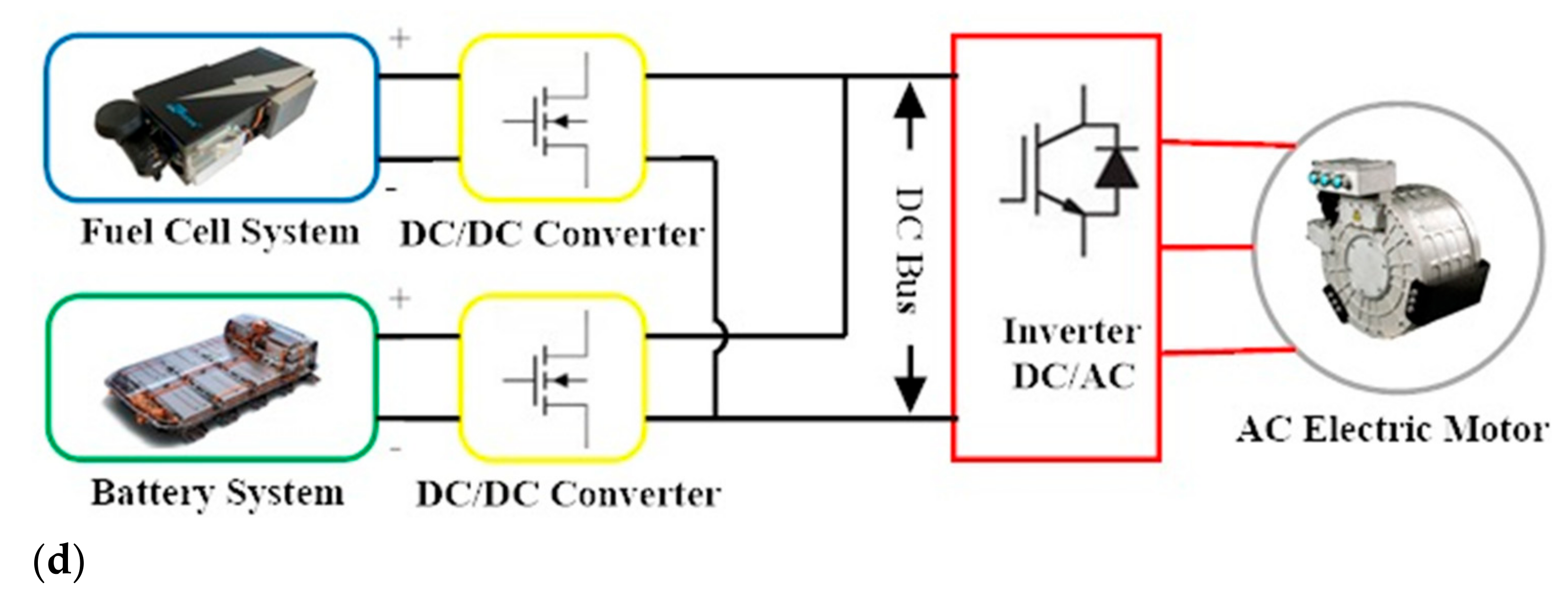

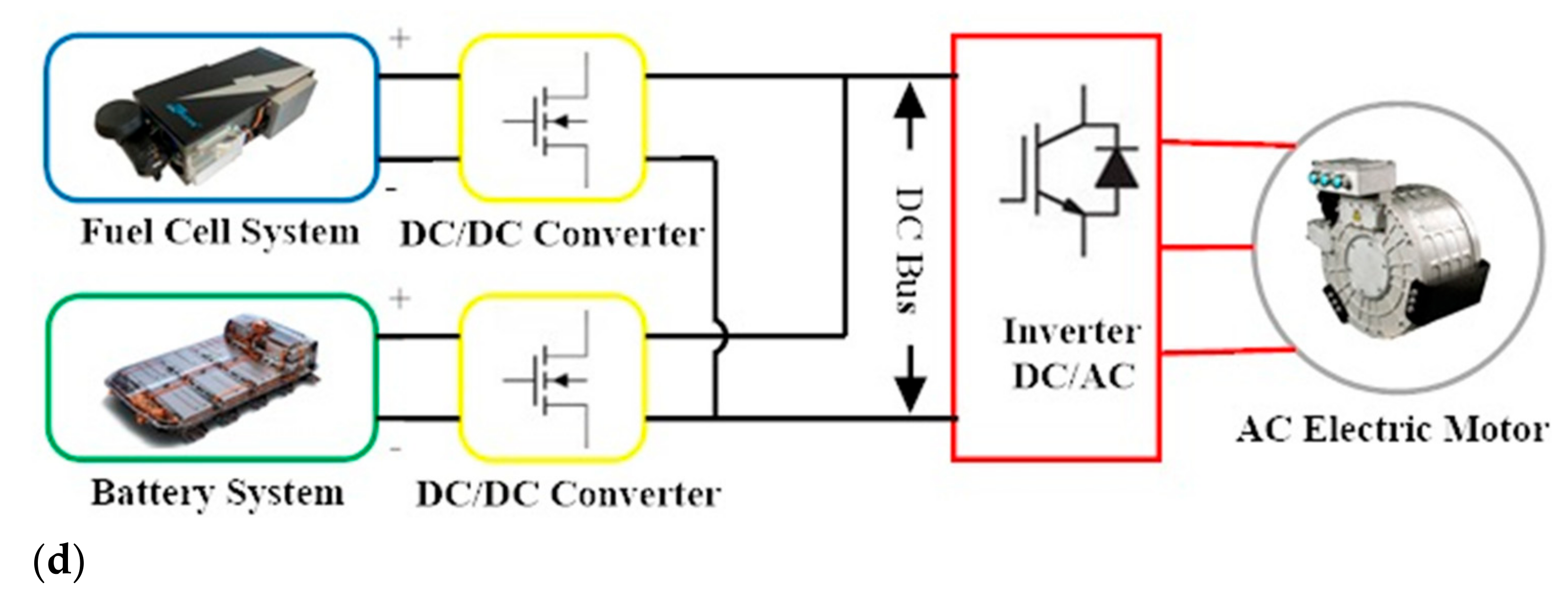

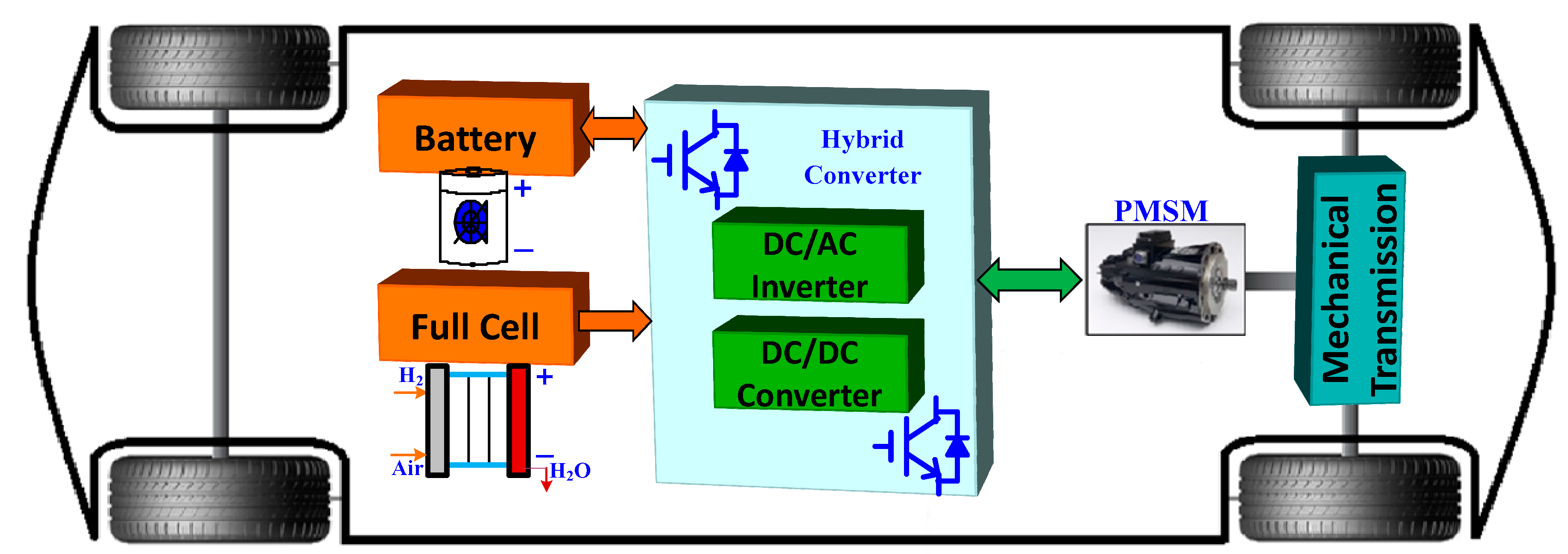

Lets investigate some of the impacts of industry trends on design and test of DCDC converters. T odays electric vehicles cost on average 12000 more to produce than a conventional car with a combustion. DCDC converters for electric vehicles The different configurations of EV power suppl y show that at least one DCDC converter is necessary to interface the FC the Battery or the Supercapacitors module to the DC-link.

Battery Pack The battery pack is made up of multiple Lithium-ion cells and stores the energy needed to run the vehicle. A real-time MCU can perform both digital power and motor control in a highly integrated design to improve efficiency while conserving valuable space. The components are described below.

Battery packs provide direct current DC output. During charging the proposed converter functions as a DAB converter providing galvanic isolation. Hybrid and EV powertrains see the battery DCDC converters onboard charger and traction inverter housed in separate enclosures.

DCDC converters constitute an entire subcategory of electrical engineering. The DCDC buck converter is a key component in all HEVEV architectures converting the higher voltage boardnet MH 48 V or EVHEV 100s of V to the traditional 12 V boardnet from where most electrical loads are powered. What is powertrain integration.

Electric-vehicle maufacturers batter suppl-chai strateies Web 2017 GES_AutomotiveMobility_EV Exhibit 2 of 5 riginal euipment manufacturers follow varying powertrain and battery supply-chain strategies for electric vehicles 1DC-DC converter and AC-DC inverter. With the help of the right converter we can bridge this gap without having to resort to a larger prohibitively-heavy battery. Powertrain Integration for Electric Vehicles June 7.

Apr 28 2021. DC-AC Converter The DC supplied by battery. The long-term trend will be to move towards bi-directionality where the charger also feeds power from the car.

Design of the powertrain boost converter is challenging because the converter must be rated at high peak power while efficiency at medium-to-light load is critical for the vehicle. High-voltage DCDC converters for electric vehicles Efficiently converts power A DCDC converter changes the higher voltage of the battery to lower voltage to power infotainment and safety systems. This state-of-the-art lab provides various types of electric powertrain testing such as performance testing endurance testing and functional testing of e-Motors Inverters DC-DC.

Our integrated circuits and reference designs help you create DCDC converter designs that efficiently transfer energy to and from one power rail to another in systems ranging from 12 V to 800 V. The DC-DC converter is designed to provide 500W with a 200-400V input and a 12-15V adjustable output.

Https Training Ti Com Sites Default Files Docs Analog Ac Dc And Isolated Dc Dc Solutions For Automotive Hev Ev Applications Det Tech Day 9 10 18 Mo B 0 Pdf

Energies Free Full Text Dc Dc Converter Topologies For Electric Vehicles Plug In Hybrid Electric Vehicles And Fast Charging Stations State Of The Art And Future Trends Html

Energies Free Full Text Fuel Cell Electric Vehicles A Brief Review Of Current Topologies And Energy Management Strategies Html

High Voltage Dc Dc Converter Generation 3evo

Dc Dc Converters For Electric Vehicles Intechopen

![]()

Increase The Range Of Ev With The Same Battery Part Iii Silicon Mobility

Dc Dc Converters For Electric Vehicles Intechopen

Figure 4 From Integrated Dc Dc Converter Design For Electric Vehicle Powertrains Semantic Scholar

![]()

Increase The Range Of Ev With The Same Battery Part Iii Silicon Mobility

Hybrid Electric Vehicle Dc Dc Converter Design And Test Challenges Microwave Product Digest

Emc Design Techniques For Electric Vehicle Powertrain Modules In Compliance Magazine

Schematic Of The Bidirectional Dc Dc Converter Download Scientific Diagram

Technologies And Components For Designing Electric Vehicles

Figure 1 From Integrated Dc Dc Converter Design For Electric Vehicle Powertrains Semantic Scholar

![]()

Increase The Range Of Ev With The Same Battery Part Iii Silicon Mobility

Analysis And Modeling Of A Bidirectional Multiport Dc Dc Power Converter For Battery Electric Vehicle Applications Semantic Scholar

Sustainability Free Full Text Energy Saving Of Battery Electric Vehicle Powertrain And Efficiency Improvement During Different Standard Driving Cycles Html

Dc Dc Converters For Electric Vehicles Intechopen

Simplified Block Diagram Of Battery Ev Powertrain Vin V Hvdc V And Download Scientific Diagram

Post a Comment for "Integrated Dc-dc Converter Design For Electric Vehicle Powertrain"